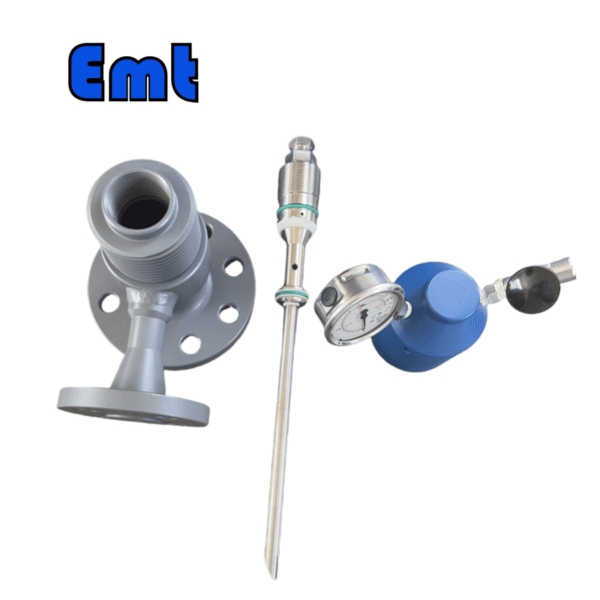

A stainless steel chemical injection quill is a specialized tool designed for precise chemical dosing in pipelines. Built from corrosion-resistant stainless steel, it ensures durability in harsh environments. Its purpose is to deliver chemicals efficiently while minimizing wear on the pipeline system.

Purpose and Functionality

The primary purpose of a chemical injection quill is to introduce chemicals into a fluid stream in a controlled manner. By doing so, it helps in processes such as:

- Corrosion inhibition – Preventing pipeline degradation caused by corrosive substances.

- Scale prevention – Reducing mineral buildup that could obstruct fluid flow.

- pH adjustment – Maintaining the right chemical balance in fluids.

- Biocide injection – Eliminating bacteria and microbial growth in pipelines.

A stainless steel chemical injection quill ensures that these chemicals are evenly distributed within the pipeline, preventing localized concentration that could lead to damage.

Material and Durability

Stainless steel is selected as the primary material for these quills due to its corrosion resistance, strength, and longevity. Pipelines often carry aggressive chemicals, extreme temperatures, and high-pressure fluids, making stainless steel an ideal choice. Common stainless steel grades used include 304, 316, and 316L, which provide excellent resistance to rust, oxidation, and chemical attack.

Design and Components

A typical stainless steel chemical injection quill consists of several key components:

- Injection tube – Extends into the pipeline to ensure proper chemical mixing.

- Check valve – Prevents backflow of fluids, protecting the injection system.

- Compression fittings – Securely attach the quill to the pipeline.

- Mounting connections – Allow easy installation and maintenance.

Some advanced quills may also include diffusers or multi-port injection tips to further improve chemical dispersion.

Advantages of Using a Stainless Steel Injection Quill

- Corrosion Resistance – Withstands harsh chemicals and extreme environments.

- Enhanced Safety – Prevents chemical leakage and backflow into the system.

- Precise Injection – Ensures accurate dosing of chemicals, reducing waste.

- Longevity – Stainless steel construction extends the lifespan of the quill.

- Easy Maintenance – Designed for quick installation and replacement.

Applications in Various Industries

- Oil & Gas – Used in pipelines to inject corrosion inhibitors, demulsifiers, and biocides.

- Water Treatment – Helps in chlorine or pH adjustment in municipal and industrial water systems.

- Chemical Processing – Ensures accurate dosing of reactants in production processes.

- Power Plants – Used in boiler water treatment to prevent scaling and fouling.

Selection of EMT Stainless Steel Chemical Injection Quill

| Model | |||||||||||||||||||||||||||

| SI | Chemical Injector Quill | ||||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | ||||||||||||||||||||||

| – Code | Injection Tube | ||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | ||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | ||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | ||||||||||||||||||||||||

| 4 | i.e. INCONEL | ||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | ||||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | ||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | ||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | ||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | ||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | ||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | ||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | ||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | ||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | ||||||||||||||||||||||||

| For Example, SI-P221-N12-S122-L4″-T22 | |||||||||||||||||||||||||||

Parameters

| Category | Details |

| Product Information | |

| Product Name | Chemical Injection Quill |

| Brand Name | EMT Pigging |

| Condition | New |

| Type | Injection & Sampling System |

| Certification | ISO 9001 |

| Warranty | 1.5 years |

| Place of Origin | Liaoning, China |

| Physical Specifications | |

| Weight (KG) | 5 |

| Package Size (cm) | 35 x 40 x 60 |

| Gross Weight (Package, kg) | 8 |

| Material and Construction | |

| Sealing Material | Fluororubber |

| Solid Plug Assembly | 316L Stainless Steel |

| Injection Tube | 316L Stainless Steel |

| NPT Nozzle | 316L Stainless Steel |

| Flange Material | ASTM A105N |

| Operational Parameters | |

| Working Temperature (°C) | -20 to 200 |

| Operation Temperature (°C) | -20 to 150 |

| Working Pressure (LB) | 150LB, 300LB, 600LB, 900LB, 1500LB |

| Pressure Rating (PSI) | 6000 PSI or as per Flange Size |

There are no reviews yet.