Introduction to EMT Pig Detectors

EMT Pig Detectors are advanced devices designed for precise detection. They identify pipeline inspection gauges, known as “pigs,” within pipelines. These detectors are crucial for efficient pipeline maintenance, particularly in the oil and gas industries. Pipeline integrity and cleanliness are paramount in these sectors. The detectors are equipped with state-of-the-art sensor technology. This technology signals the arrival and departure of pigs. Operators can monitor cleaning, inspection, or blockage removal in real time. Constructed for harsh environments, the detectors operate in subterranean or underwater pipelines. They provide consistent performance, reducing the risk of costly operational issues. These issues include disruptions or accidents caused by undetected maintenance problems.

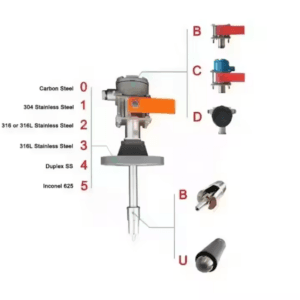

Different Indicator Types

| Indicator Types | ||||

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Popper Type:

This indicator is mechanically activated when a pig passes the detector point. The popper type typically features a visible flag or pop-up indicator that physically changes position to signal the presence of a pig. It’s straightforward and reliable, primarily used in applications where electronic signaling is not necessary or feasible.

Manual Reset Flag:

Similar to the popper type, this indicator also features a visible flag that activates when a pig is detected. However, it includes a manual reset function that requires an operator to physically reset the flag after each detection. This feature ensures that each pig passage is noted and recorded manually, preventing any oversight and confirming the passage of every pig.

Manual Reset Flag Combined with Electrical Signals:

This type integrates the manual reset flag with electrical signaling capabilities. When a pig passes, it triggers both the visible flag and an electrical signal, which can be linked to a control room or a monitoring system. This dual notification system enhances response efficiency, allowing for immediate electronic tracking and data logging alongside the manual check.

Date and Time Display Combined with Electrical Signals:

The most advanced option, this type combines the features of an electrical signal with a display system that records the date and time of each pig’s detection. This feature is particularly useful for detailed monitoring and record-keeping, enabling precise tracking of maintenance schedules and operational efficiency. It provides critical data that can be used for analysis and future planning, improving the overall management of pipeline operations.

Parameters of Pig Detectors

| Specification | |

| Type | Intrusive |

| Connection Type | Flange connection |

| Indicator Feature | Manual reset flag; Date and time display combined with electrical signals (optional) |

| Installing Type | 2″ Flange, ASME B16.5 (CLASS 150-2500) |

| Plug Body Length | 200 mm or as per actual needs |

| Insert Depth Adjustment | 20 mm |

| Operating Temperature | -20 to 120°C or as per customer requirements |

| NACE | MR 0175 |

| Ingress Protection | IP66 |

| Explosion-Proof Class | Exd II BT4 |

| Remove Under Pressure | No |

| Trigger Type | Bi-directional (Uni-directional trigger also available) |

| Internal Part Material | PTFE Coated A105N (Options: 304SS, 316LSS, DSS, INCONEL, or as per MR) |

| Junction Box Material | Aluminium alloy or 316SS |

| Switch Type | DPDT or 2*SPDT |

| Switch Rating | DC24V 3A or DC24V 5A |

Applications of EMT Pig Detectors

Pig detectors are essential tools in the maintenance and operation of pipeline systems, providing critical support in various applications. One primary use of these devices is in the cleaning and maintenance of pipelines. Pig detectors precisely locate pipeline inspection gauges, or “pigs.” These detectors ensure thorough and efficient cleaning processes. This is crucial in industries like oil, gas, and chemicals. Pipeline cleanliness directly impacts the quality and safety of transported materials. Additionally, pig detectors help prevent blockages. Blockages can increase pressure and risk pipeline failure. This enhances operational safety and reliability.

In addition to maintenance, pig detectors are invaluable for the inspection and monitoring of pipelines. They enable operators to track the movement of inspection pigs that assess the integrity of the pipeline infrastructure. This capability allows for the early detection of faults such as cracks, corrosion, and other structural weaknesses that could compromise pipeline safety. By providing real-time data on the pig’s location, these detectors facilitate timely interventions, reducing downtime and expensive repairs. This continuous monitoring is crucial in preemptive maintenance strategies, helping to extend the lifespan of pipeline assets and ensure compliance with safety regulations.

Furthermore, pig detectors play a critical role in operational logistics within pipeline systems. They confirm the successful launch and receipt of pigs, which is vital for scheduling maintenance and inspection operations without disrupting the product flow. The ability to accurately signal the arrival and departure of pigs ensures that pipeline operations are not only efficient but also aligned with the planned maintenance schedules. This coordination is vital in minimizing operational disruptions and optimizing the throughput of the pipeline system, thereby ensuring economic efficiency and operational excellence in industries reliant on continuous pipeline operations.

There are no reviews yet.