LPR Corrosion Monitoring System Product

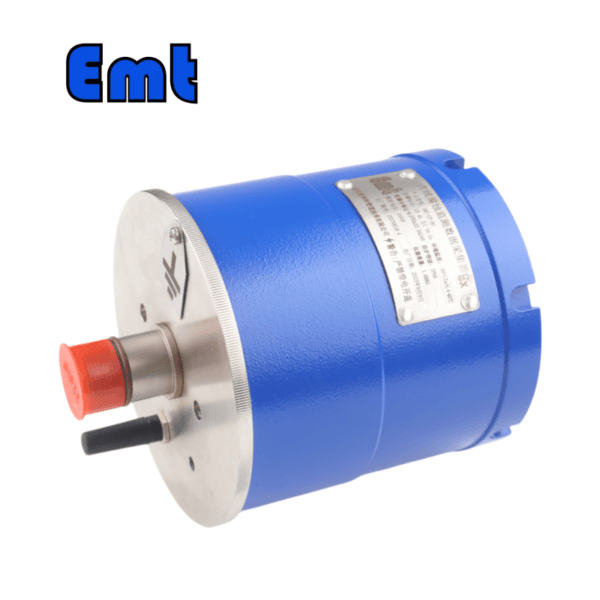

HS5000-LPR Corrosion Data Collector

The HS5000-LPR Corrosion Data Collector effectively measures the corrosion rate of metals and outputs this data to the upper computer system in real time through related protocols. Therefore this capability ensures that operators can monitor corrosion levels continuously, enabling timely decision-making.

Product and Function

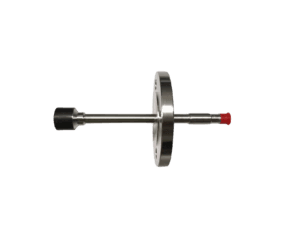

The product primarily consists of four key components: the corrosion data collector, an optional extension cable, the corrosion probe, as well as the electrode. Together, these components work seamlessly to provide accurate and reliable corrosion measurements.

Technical Features of LPR Corrosion Monitoring System

(1) The product combines the current advanced computing technology and data analysis technology for accurate corrosion rate measurement.

(2) Besides, it is commonly used for real-time monitoring of corrosion rates in metal pipelines in electrolyte environments in industries such as oil, power, and water treatment, as well as for laboratory evaluations of corrosion inhibitors and on-site injection control.

(3) The collector can also be directly connected to the probe or connected in a split manner through a cable entry. In this way, flexibility is ensured, allowing for easier installation based on specific site requirements.

(4) Additionally, the system supports connecting different types of probes and electrodes, including cylindrical probes, flat probes, and standard insert probes. There are various options for connections, such as threaded process connections, flange process connections, welded base plug-in types, and flange base press-in types, offering versatility for different applications.

(5) Furthermore, the measurement cycle can be set from 10 minutes to 24 hours, providing operators with the ability to customize monitoring frequency based on their operational needs.

(6) The corrosion rate can be transmitted to factory operators via an RS-485 signal. Moreover, it can be uploaded to the corrosion platform through a 4G wireless signal or downloaded via Bluetooth from the data collector to an explosion-proof handheld device or a local computer, ensuring data accessibility in various formats.

(7) Finally, the probe can be used at temperatures up to 260 degrees Celsius. Specifically, the low-pressure removable type probe can withstand pressures up to 10.3 MPa, while the high-pressure removable type probe can endure pressures up to 41.3 MPa, making them suitable for a wide range of harsh environments.

Application Value of LPR Corrosion Monitoring System

- For onsite operators and corrosion engineers:

- Real-time, online monitoring of corrosion rates to control corrosion risks.

- Outputs RS-485 standard signal.

- For production units:

- Automation of the corrosion control process.

- Reduces the need for asset replacement, extending asset life (selective maintenance rather than scheduled overhauls).

- Optimizes the choice of corrosion inhibitors (type selection, timing of addition, dosage).

- For enterprises:

- Saves over 20% in corrosion costs.

- Reduces the occurrence of accidents.

- Enhances corporate competitiveness and establishes a positive corporate image.

Parameters

LPR Corrosion Data Collector Technical Specification

| Technical Specifications | |

| Output signal | Wired form: RS-485 signal Wireless form: LORA, 4G/5G wireless network signalRecord form: Internal storage Bluetooth download |

| Power supply voltage: | 7-36VDC |

| Instrument Power Consumption: | 5.4W(wired) |

| Linearity: | 0.0015% non-linearity |

| Resolution: | 17 bit |

| B Value: | 25.6 mV |

| Accuracy: | ±0.2% F.S(full scale) |

| Corrosion Rate Range: | When the electrode area is 1cm², the measurement range is 4X10^-4 to 10 mm/year |

| Operational and Storage Conditions | |

| Collector Operating Temperature: | -40~70℃ |

| Collector Storage Temperature: | -40~85℃ |

| Structural Parameters | |

| Protection Class: | IP66 |

| Housing Material: | Cast aluminum or PVC, aviation aluminum, stainless steel (customizable) |

| Process Interface: | 7/8-20UNEF (insertion probe) |

| Electrical Connection: | M20*1.5mm |

| Cable Type: | RVVP 2*1.5mm² (minimum application standard) |

| Installation: | Probe directly mounted on the pipeline, while collector can be integrated or installed separately through a cable |

| Weight: | 500g |

| Direct Connection between Probe and Collector: Split Configuration Accessories: Split Configuration Connection Cable: | S22-16 adapter Interface: MS-14-6S double female Cable Length: 1-3 meters (customizable) |

| Certifications | |

| Hazardous Area Certification: | EX-d IIC T4 Gb |

LPR Corrosion Probe Technical Specification

| Technical Specifications | |

| Working Temperature: | Customizable from 0 to 260°C (customization required for different environments) |

| Electrode Structure Types: | Cylindrical three-finger type Plate-shaped three-piece type Ring-shaped three-ring type Other custom forms |

| Materials Probe Body: Electrodes:

| Fixed and telescopic are 316 stainless steel or specified more corrosion-resistant alloy; Custom can be made from PVC, POM, PEEK, PTFE, Nylon, and other materials; Material matching the monitored site carrier metal is essential for accurate corrosion assessment. |

| Probe Dimensions Probe Length: Entry length: | You can customize metal rod probes to any length between 150 mm and 2000 mm. You can also customize flexible cable probes to any length between 150 mm and 4000 mm. For metal rod probes, you can customize the entry length to any length between 40 mm and 500 mm. Similarly, for flexible cable probes, you can customize the entry length to any length between 40 mm and 3800 mm. |

| Connection Types between Probe Body and Measuring Electrodes Cylindrical Electrodes: Plate-shaped Electrodes: Ring-shaped Electrodes: Custom Electrodes: | Connection via threaded stud tightening Insertion into insulating parts Press-fit into insulating parts Different connections designed according to different shapes |

| Probe Body Filling: | High-Temperature Probes (above 150°C): Filled with high-temperature resistant insulating ceramic materials and cured Low-Temperature/Room-Temperature Probes (below 150°C): Filled with epoxy potting compound and cured

|

| Electrical Connection Type: | High-temperature sintered aviation plug with external thread |

| Electrical Connection Thread Size: | Insertion Probes: 7/8-20UNEF–MS-14-6S male head |

| Installation Structure and Opening Size Telescopic Probes: High-Pressure Detachable Probes:

| Installation structure: Probe body + sealing packing box + flange bearing seat + flange valve + flange jumper Opening and connection size: DN40 or DN50 (same configuration as valve fittings) Installation standards such as: HG/T20615-2009 CL150 DN50 RF, HG/T20592-2009 DN50 PN25 RF Installation structure: Probe body + screw-in plug + high-pressure carrier + heavy-duty cap + extension adapter Opening size: DN50 (same configuration as valve fittings) |

There are no reviews yet.