The EMT Polyurethane Crisscross Polly Foam Pig for Pipeline is a critical tool for industries that rely heavily on pipeline systems for their operations. Its robust design, tailored to meet specific industry needs combined with its operational efficiency and adherence to quality standards, makes it an essential asset for maintaining the integrity and functionality of pipeline infrastructure. Whether for routine cleaning or for addressing complex blockages, EMT’s foam pig offers a reliable, effective solution for ensuring uninterrupted pipeline operations across a variety of sectors.

Product Overview

Product Name: EMT Polyurethane Crisscross Polly Foam Pig

Manufacturer: EMT Pigging

Material: Polyurethane

Available Sizes: 2 inches to 60 inches

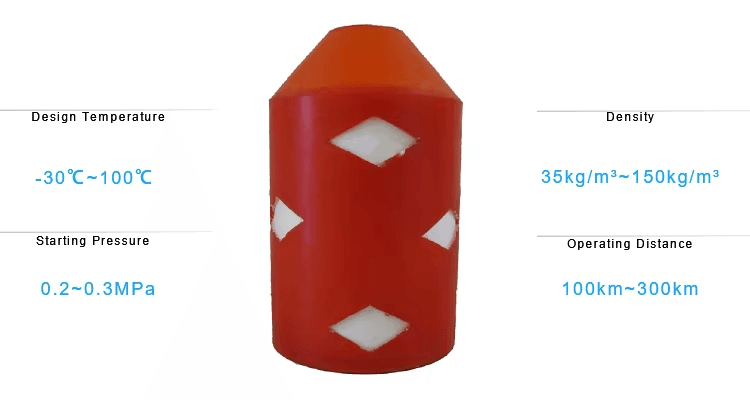

Density: 35 kg/m³ to 150 kg/m³

Type: Criss Cross Polly Pig

Color: Red

Condition: New

Certification: ISO9001

Key Features and Design

1.High-Grade Polyurethane Material

The choice of high-grade polyurethane for the construction of the EMT foam pig is pivotal. Polyurethane is renowned for its exceptional properties including great flexibility, excellent wear resistance, and substa ntial resilience to both physical and chemical abrasions. This material ensures that the foam pig can withstand the harsh conditions within pipelines, such as extreme pressures, variable temperatures, and corrosive substances, making it durable and reliable for repeated use.

2.Crisscross Scrubbing Design

Central to its functionality, the crisscross pattern on the EMT foam pig is not merely aesthetic but serves a critical operational purpose. The unique pattern increases the surface area of the pig, which in turn enhances its ability to engage with and dislodge debris and deposits from the pipeline walls. This design is particularly effective against stubborn or hardened deposits that typical smooth-surface pigs might leave behind. The crisscross pattern acts like bristles on a brush, scrubbing away residues thoroughly and ensuring a cleaner pipeline after each pass.

3.Size Versatility

EMT’s foam pig is engineered to cater to a broad spectrum of pipeline diameters, ranging from 2 inches to 60 inches. This wide range of sizes makes the pig versatile enough to be used in various installations, from small diameter service lines to large transmission mains. This adaptability is crucial for companies that operate a diverse array of pipeline diameters and require a consistent, effective cleaning solution across all their pipeline assets.

4.Variable Density Configuration

Supporting its size versatility, the EMT foam pig’s variable density range from 35 kg/m³ to 150 kg/m³ allows for further customization. Different densities are pivotal in targeting specific cleaning needs; lower densities are typically used for lighter cleaning and dewatering tasks, while higher densities are suited for more aggressive cleaning actions, such as removing tougher and more adherent deposits. This range of densities ensures that the foam pig can be tailored to the specific requirements of the pipeline’s condition and the nature of the material being transported or removed.

5.Customization and Applications

The ability to customize the foam pig according to specific pipeline conditions extends beyond size and density. Depending on the application, the foam pig can also be equipped with various coatings or additives. For instance, abrasive coatings can be added for more challenging cleaning tasks, or the foam can be impregnated with agents that help reduce static build-up in gas pipelines. Such customization options make the EMT foam pig not only a tool for cleaning but also a versatile device . It is capable of addressing a wide range of operational challenges in pipeline maintenance.

Name | EMT Manufacturing Customized PU Coated Criss-cross Bristle Polly Pig Foam | ||||

Material | Polyurethane | ||||

Light Density | 0.02-0.3g/m3 | ||||

Medium Density | 0.08-0.12g/m3 | ||||

Heavy Density | 0.13-0.16g/m3 | ||||

Feature | 1.High wear resistance | ||||

2.Good cleaning performance | |||||

3.Low cost | |||||

Payment | TT/LC | ||||

Advantage | 1.They are light weight and flexible. | ||||

2. Nice cleaning efficiency. | |||||

3.Accurate location tracking. | |||||

Industry-Specific Applications

1.Building Material Shops:

In environments where pipelines are used to transport abrasive or viscous materials, the EMT foam pig ensures that these conduits are kept clear from obstructions that could hinder the flow of materials or damage the pipeline infrastructure.

2.Construction Works:

For construction sites, this foam pig plays a pivotal role in maintaining drainage and wastewater lines, helping to prevent clogs that can cause delays and create hazardous conditions.

3.Energy & Mining:

In the energy and mining sectors, pipelines often carry slurry and other particulate-laden fluids. Regular cleaning with the EMT foam pig prevents buildup that can reduce the efficiency of these systems or even lead to pipeline failure.

4.Oil & Gas Pipeline Pigging:

The foam pig is especially valuable in the oil and gas industry. Where it is used to remove wax, hydrocarbons, and other organic deposits. This maintenance ensures optimal flow rates and extends the lifespan of the pipeline.

Operational Benefits

1.Extended Operation Range:

The EMT foam pig can operate over distances ranging from 100 km to 300 km, making it ideal for long pipelines where frequent access points are not feasible. This capability allows for fewer interruptions and more continuous system operations.

2.Lightweight and Durable:

With a weight of only 1 kg and packaged in a small 6x6x10 cm box, the foam pig is easy to transport and handle, reducing the labor and time involved in pipeline maintenance operations.

3.Quality Assurance:

Backed by an ISO9001 certification, the EMT foam pig meets stringent quality standards. The company also provides a machinery test report and conducts a video outgoing-inspection for each unit, ensuring that each product delivered performs at its peak.

4.Warranty and Support:

EMT offers a six-month warranty on their foam pigs, reflecting their confidence in the product’s durability and effectiveness. This warranty is complemented by comprehensive customer support, ready to address any operational questions or issues that may arise.

Contact Us

For more information or to discuss custom designs tailored to your specific requirements, please contact us. We are ready to provide innovative solutions that match your needs in pipeline maintenance and monitoring.

There are no reviews yet.