EMT Corrosion Coupon Retrieval Tools are specialized devices used in the oil, gas, and water industries to safely and effectively remove corrosion coupons from pipelines and vessels while they are under pressure. These tools are essential for conducting corrosion monitoring and for ensuring the integrity and longevity of infrastructure. Below is an overview of the features, operation, and benefits of using EMT Corrosion Coupon Retrieval Tools.

EMT Corrosion Coupon Retrieval Tools are vital for maintaining the health and operational efficiency of pipelines and other metallic infrastructures. Featuring a robust design, these tools offer ease of operation and include multiple safety features, providing a straightforward solution for corrosion monitoring. Consequently, they ensure that industry professionals can maintain infrastructure integrity, reduce maintenance costs, and enhance operational safety.

Features

Safety Mechanisms: EMT tools are designed with safety as a priority. They often include features such as double block and bleed systems, which ensure that operators can retrieve corrosion coupons without exposing themselves to the process fluid or to high-pressure environments.

High-Quality Materials: Constructed from durable materials such as stainless steel, these tools are resistant to the harsh conditions found within industrial pipelines, including high temperatures and corrosive substances.

Versatility: EMT tools work with various types of access fittings and can handle a wide range of pipeline diameters and pressures, making them suitable for diverse operational needs.

Ease of Use: Engineers design these tools for easy operation, allowing for quick and efficient coupon retrieval without significant system downtime or disruption.

Operation of EMT Corrosion Coupon Retrieval Tools

The operation of these tools typically follows a standardized procedure to ensure safety and efficiency:

Installation: The operator attaches the retrieval tool to a valve connected to the access fitting on the pipeline or vessel, usually under full line pressure.

Retrieval: Once secured, the operator manipulates the tool to access the corrosion coupon holder inside the pipeline. The operator then secures the coupon and isolates it from the process environment using the tool’s integrated valves.

Removal: After securing and isolating the coupon, the operator safely withdraws it from the pipeline and brings it out through the retrieval tool to the exterior for inspection.

Benefits

Accurate Corrosion Monitoring: These tools enable regular retrieval of corrosion coupons. Operators can obtain accurate measurements of corrosion rates. This data is crucial for assessing corrosion inhibitors’ effectiveness. It also aids in planning maintenance schedules.

Minimized Downtime: The coupons can be retrieved without shutting down the system. They also don’t require draining the pipeline. These tools help minimize operational downtime.

Enhanced Safety: The tools’ design minimizes the risk of leaks. It also reduces exposure to hazardous substances. Thereby, it enhances the safety of operations.

Cost-Effectiveness: These tools facilitate proactive corrosion monitoring. They help prevent severe corrosion damage. This can lead to expensive repairs or pipeline failures.

Compliance: Regular monitoring and maintenance are facilitated by these tools. They help ensure compliance with industry standards and regulations. Compliance can be critical for legal and environmental reasons.

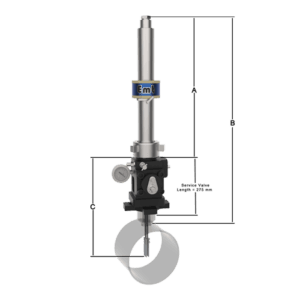

Parameters of Retrieval Tool

| Letter | Description | Maximum Pipeline Size | ||

| 12″ | 24″ | 36″ | ||

| A | Retriever (mm) | 710 | 1000 | 1300 |

| B | Retriever and Service Valve (mm) | 985 | 1275 | 1575 |

| C | Stroke Available (mm) | 600 | 881 | 1184 |

| Weights (kg) | 25.4 | 27.6 | 30 | |

| Name | Mechanical Retrieval Tool with Double valve | ||||||

| Max. Device Length (mm) | 150 | 240 | 350 | 425 | 640 | 920 | 1170 |

| Mechanical Retrieval Tool Length extended, including single valve | 1328 | 1508 | 1733 | 1878 | 2308 | 2868 | 3368 |

| Removal clearance with single valve | 1628 | 1808 | 2033 | 2178 | 2608 | 3168 | 3668 |

| Mechanical Retrieval Tool weight (kg) | 23.5 | 25.5 | 17.5 | 29.5 | 34 | 40 | 45.5 |

| Retriever kit approximate weight (kg) including double valve (13 kg) | 74 | 76 | 78 | 80 | 84 | 90 | 96 |

Applications of Retrieval Tool

Corrosion coupon retrieval tools play a vital role in the maintenance and longevity of industrial systems by allowing for the direct measurement of corrosion rates in pipelines and vessels. Consequently, here are several key applications of these tools across various industries:

1. Oil and Gas Industry

Pipeline Monitoring:

Regularly retrieving corrosion coupons from pipelines carrying crude oil, natural gas, or refined products helps monitor the corrosiveness of the contents and the effectiveness of corrosion inhibitors.

Well Testing:

In oil and gas wells, these tools help determine the corrosion rate of downhole equipment, enabling timely interventions to prevent failures.

2. Chemical Processing Industry

Process Monitoring:

Corrosion coupon retrieval tools are extensively used in chemical plants to track corrosion rates. Specifically, they monitor the integrity of reactors, storage tanks, and pipelines that handle corrosive chemicals.

Material Compatibility Testing:

Furthermore, these tools play a crucial role in evaluating the suitability of construction materials under various chemical exposures. This assists in making informed decisions for the selection of materials for new installations or upgrades.

3. Water Treatment and Distribution

Water Systems Monitoring:

These tools are essential for assessing corrosion in municipal water supply systems, including pipes and storage tanks, to ensure water quality and system reliability.

Efficiency Assessment:

They help verify the effectiveness of corrosion control measures such as pH adjustments and the addition of corrosion inhibitors.

4. Power Generation

Cooling Systems Monitoring:

Retrieval tools are used to monitor corrosion within cooling water systems, which are critical for maintaining the efficiency and safety of power generation facilities.

Boiler Inspection:

Corrosion coupons provide data on the corrosive effects of boiler water treatment chemicals and feed water quality.

There are no reviews yet.