1. Order Information of Stainless Steel Injection Quill

Access Fitting Body

| Model | Stainless Steel Injection Quill | |||||

| EMT-CIPA | Access Fitting Body | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating & pipe size” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″Tee | |||||

| 2 | 1/2″Tee | |||||

| 3 | 3/4″Tee | |||||

| 4 | 1″Tee | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example:EMT-CIPA-0F600#RF-2-1/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, 1/2″NPT(F)Tee, Protective Cover in CS without hole 0F600#RF: 0F_ Access Fitting Body is Flanged in CS , 600#RF _Size is 2″ANSI 600#RF , 2:Tee size is 1/2NPT(F) 1: Protective cover type is without hole /CS: Material in CS | ||||||

Sampling & Injection Point

| Model | ||||||||||||||||||||||||||||

| SI | Sampling & Injection Assembly | |||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| – Code | Injection Nut | |||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | No Request | 0 | CS | |||||||||||||||||||||||||

| 1 | 1/4″ | 1 | 316SS | 3 | DSS | |||||||||||||||||||||||

| 2 | 1/2″ | 2 | 316LSS | 4 | INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | 1/4″ | 1 | 316SS | 1 | Open | |||||||||||||||||||||||

| 2 | 1/2″ | 2 | 316LSS | 2 | Quill | |||||||||||||||||||||||

| 3 | DSS | 3 | Cap & Core | |||||||||||||||||||||||||

| 4 | INCONEL | |||||||||||||||||||||||||||

Code | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | No Request | 0 | CS | |||||||||||||||||||||||||

| 1 | 1/4″Nipple | a | 1/4″Nipple and Valve | 1 | 316SS | |||||||||||||||||||||||

| 2 | 1/2″Nipple | b | 1/2″Nipple and Valve | 2 | 316LSS | |||||||||||||||||||||||

| 3 | 3/4″Nipple | c | 3/4″Nipple and Valve | 3 | D SS | |||||||||||||||||||||||

| 4 | 1″Nipple | d | 1″Nipple and Valve | 4 | INCONEL | |||||||||||||||||||||||

| 5 | 1/4″Flange | e | 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | 1/2″Flange | f | 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | 3/4″Flange | g | 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | 1″Flange | h | 1″Nipple end Flange | |||||||||||||||||||||||||

| For Example:SI-P221-N12-S122-L4″-T22 SI:Sampling & Injection Assembly,P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing,N12:Injection Nut Connection Size is 1/4″and Material is 316LSS,S122:Injection Tube Connection Size is 1/4″ and Material is 316LSS.Type of nozzle is quill,L4″:For 4″pipe. T22: Nipple of Tee Connection Size is 1/2″, Nipple material is 316LSS | ||||||||||||||||||||||||||||

A set of Sampling & Injection Systems:

EMT-CIPA-0F600#RF-2-1+ SI-P221-N12-S122-L4″-T22

The EMT Stainless Steel Injection Quill is a highly specialized device designed for the accurate and safe injection of chemicals into pipelines under pressure. As a crucial component of the EMT Injection System, this quill ensures that corrosion inhibitors and other essential chemicals are efficiently distributed within the pipeline system, thereby minimizing corrosion and maintaining the integrity of the pipeline.

2. Key Features of the EMT Stainless Steel Injection Quill:

- Material Construction: The quill is constructed from high-grade stainless steel, ensuring durability and resistance to corrosion. This makes it suitable for use in harsh chemical environments and extends its operational lifespan.

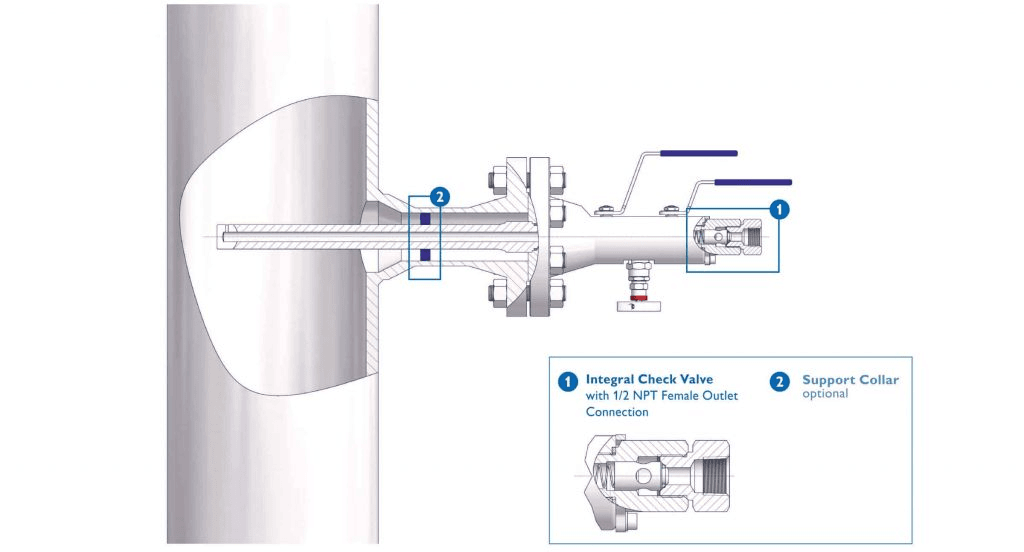

- Design and Operation: The injection quill features a quill-type nozzle, which is designed to optimize the distribution of chemicals into the flow of the pipeline. This design helps to prevent the chemicals from clinging to the pipe walls, promoting more effective treatment and reducing waste.

- Mounting Options: It offers various mounting options to accommodate different pipeline configurations and requirements. Common mounting types include a 2″ ANSI flange or a 1″ NPT ball valve, providing versatility and ease of installation.

- Operating Conditions:

- Temperature Range: The quill can operate effectively within a temperature range of -20 ℃ to 150 ℃, making it suitable for a wide range of industrial applications.

- Pressure Rating: It is rated for pressures up to 6000 PSI, depending on flange size and configuration, which allows for use in high-pressure systems without risk of failure.

- Safety and Reliability: Designed for injection under operating pressure, the quill includes features that ensure safe and reliable operation. The robust construction and precise manufacturing standards help to prevent leaks and other potential hazards associated with chemical injection.

3. Application of Stainless Steel Injection Quill:

The EMT Stainless Steel Injection Quill is a vital component in managing the integrity and longevity of pipelines, particularly in industries where pipeline corrosion poses significant operational and safety risks. Its specific applications extend across various sectors including oil and gas, chemical processing, water treatment, and others.

By ensuring the correct dosage and thorough mixing of chemicals within the pipeline, the EMT Stainless Steel Injection Quill not only extends the life of the pipeline infrastructure but also reduces the likelihood of leaks and environmental contamination. This is especially crucial in industries where spills and leaks can have severe environmental and health impacts.

The diverse applications of the EMT Stainless Steel Injection Quill underscore its importance across various sectors. By delivering chemicals reliably and efficiently into pipelines, the quill helps industries meet safety standards, protect environmental quality, and achieve operational efficiency.

There are no reviews yet.