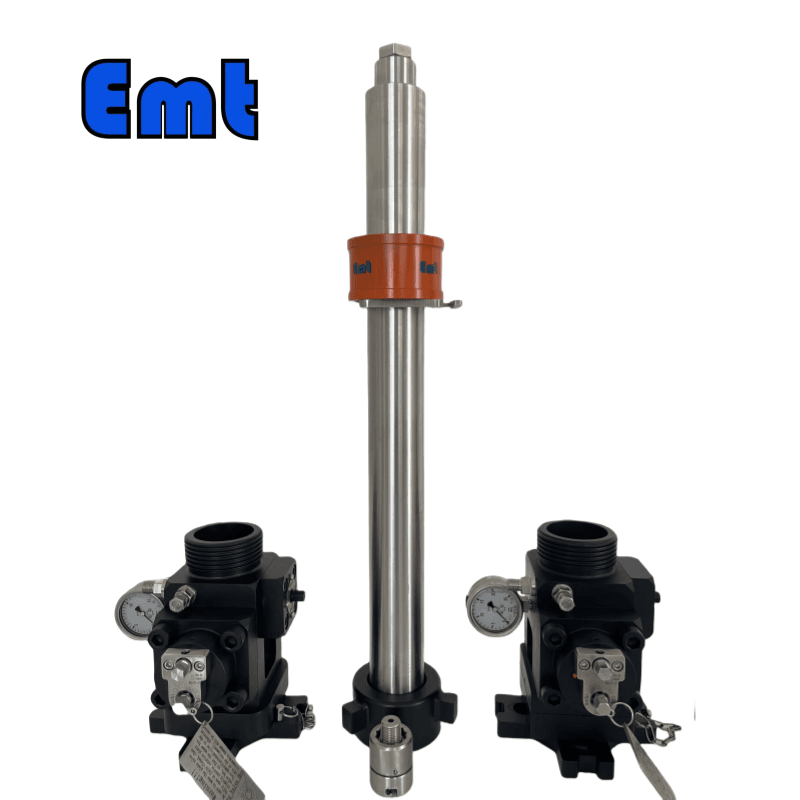

Corrosion Coupon (Retrieval) is a vital tool for assessing the extent of corrosion within pipeline systems. They provide a direct measure of the corrosive conditions inside the pipelines, facilitating timely maintenance and intervention to extend the lifespan of infrastructure. Traditional retrieval methods often require halting operations and depressurizing the system, which can lead to significant economic losses. To address these challenges, EMT has developed an innovative solution that allows for the retrieval of corrosion coupons without the need to shut down or depressurize the pipeline. This process is facilitated by the EMT-WRTV Retrievers and Service Valves, which are designed for efficient and safe operations under pressure.

Strip Coupon – Standard

(76.2mm x 19.0mm x 3.2mm)

with two (2) mounting holes.

The exposed surface area is 4.65 in2 (3,000mm2).

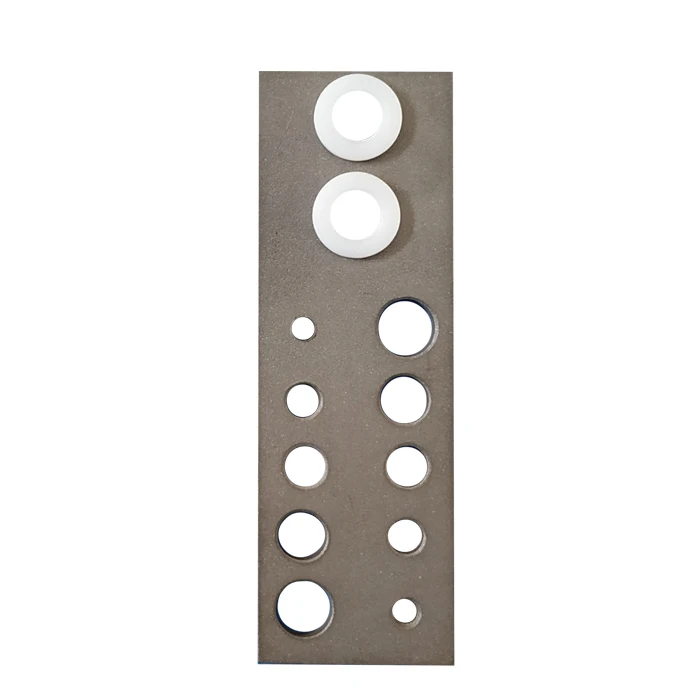

Strip Coupon – Multihole

1/16″ (76.2mm x 19.0mm x 3.2mm)

with two (2) mounting holes.

The exposed surface area is 2.65 in2 (1,709mm2).

Disc Coupon

1/16″ (Ø 31.8mm x 3.2mm) with one mounting hole. The exposed surface area is 2.65 in2 (1,709mm2).

1. Retrieval Process Description

Preparation for Retrieval

- Adapter Installation:

- Begin by safely removing the protective cover to expose the pipeline entry point.

- Unscrew and remove the existing pipe plug. This may require appropriate tools depending on the installation.

- Carefully install the Adapter in the vacated plug position. Make sure the hexagons on the Adapter align perfectly with those on the plug body to ensure a secure and leak-proof fit. Tighten securely to prevent any potential leaks under pressure.

- Service Valve and Hammer Nut Installation:

- Attach the Hammer Nut to the system first to provide a base for attaching the Service Valve.

- Connect the Service Valve to the Hammer Nut. It is crucial to ensure that the Service Valve is in the open position at this stage to facilitate the subsequent steps of the retrieval process. Secure both components tightly to withstand the system’s operational pressure.

Retriever Setup

- Attach the Retriever to the Service Valve, ensuring it is securely locked into place. This step is critical as the Retriever will be used to physically extract the corrosion coupon from within the pipeline.

Corrosion Coupon Removal

- Lowering the Plug Lifter:

- Position the Plug Lifter above the coupon using the Plug Drive.

- Rotate the Plug Drive in the direction indicated for “Removal” (typically clockwise). Apply steady downward pressure to engage the mechanism.

- If resistance is felt, continue to rotate the Plug Drive until the Plug Lifter can move smoothly.

- Once free, lift the Plug Lifter to its highest position and engage the Stop Block to secure it in place.

- Isolating the Retriever:

- Close the Service Valve to isolate the Retriever from any pipeline pressure. This step is essential to ensure safety and prevent any unintended release of pipeline contents.

- Close the Bypass Valve to maintain pressure equilibrium within the retrieval tool and prevent any internal pressure discrepancies.

- Pressure Release and Draining:

- Open the Bleed Valve to safely release all internal pressure from within the retrieval tool. This step must be handled carefully to avoid any sudden discharge of fluids or gases.

- Unscrew and open the sealing screw located at the top of the Retriever. Drain any residual liquid from the retrieval tool into an appropriate containment system. Reseal the screw after draining to prevent contaminants from entering.

Retriever Disengagement

- Carefully detach the Retriever from the Service Valve. This final step completes the removal process of the corrosion coupon. Ensure that all connections are securely closed and the system is resealed to maintain pipeline integrity.

2. Key Features of the Corrosion Coupon (Retrieval)

Material Construction

- High-Grade Stainless Steel Components. The main components of the Corrosion Coupon (Retrieval), including the Service Valve, Adapter, and Retriever, are constructed from premium stainless steel. This choice of material is critical for several reasons:

- Corrosion Resistance. Stainless steel offers exceptional resistance to a wide range of chemical agents, including acids and alkalis, which are commonly found in industrial pipeline environments. This resistance ensures the longevity and reliability of the retrieval system under harsh conditions.

- Strength and Durability. The inherent strength of stainless steel withstands high pressure and mechanical stress, ensuring that the system maintains its structural integrity over time.

- Maintenance Ease. Stainless steel is easier to clean and maintain compared to other metals, which helps in maintaining a high level of operational hygiene and efficiency.

Pressure and Temperature Capabilities

- High Pressure Tolerance. The system’s design is easy to safely handle pressures up to 45 MPa. This high-pressure capability is crucial for applications in petroleum and natural gas pipelines where operating pressures can be extremely high.

- Broad Temperature Range. With an operational temperature range from -20°C to 100°C, the retrieval system can function effectively in a variety of environmental conditions. This temperature flexibility allows the system to work in both cold climates and high-temperature industrial processes.

There are no reviews yet.