A Vertical Quick Opening Closure (QOC) is a specialized mechanical device designed to provide secure and rapid access to pressure vessels and pipeline systems. Operators typically use these closures in vertical installations and they are essential in industries such as oil and gas processing, chemical manufacturing, and utilities, where quick and frequent access to the internals of a vessel or pipeline is necessary.

Key Features of Vertical Quick Opening Closures

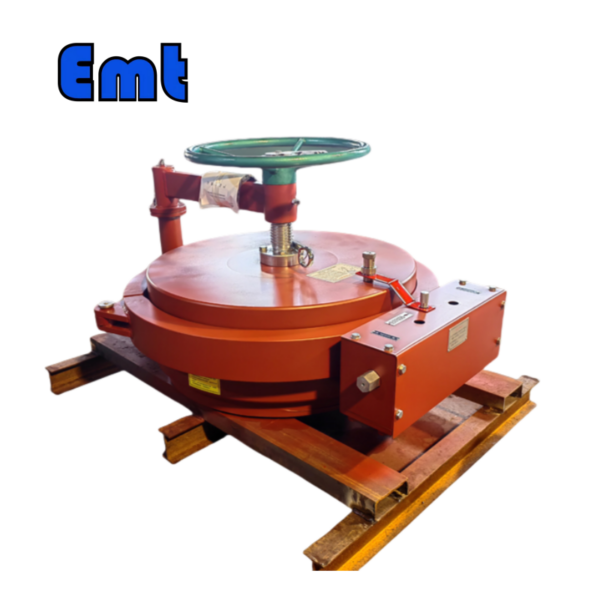

Vertical QOCs are renowned for their robust design and efficiency. They feature a closure mechanism that operators can quickly open and securely seal to minimize downtime during maintenance or inspection operations. This design often includes a locking ring or bayonet mechanism, enabling a tight seal under high-pressure conditions and ensuring safety during operations.

Vertical Quick Opening Closures (QOCs) boast a range of features that enhance their efficiency and reliability in industrial settings. They can tolerate high pressures, ideal for challenging environments like oil refineries or chemical plants. The closures provide rapid access to vessels or pipelines, significantly cutting down on maintenance and inspection downtime.

Safety is paramount with these devices. They include pressure relief valves and safety interlocks to prevent accidental openings under pressure. Made from durable materials such as carbon steel or stainless steel, Vertical QOCs resist corrosion and wear effectively. Installation and operation are straightforward, with features like handwheels or hydraulic actuators simplifying the process.

Moreover, Vertical QOCs are customizable in size, material, and pressure ratings to meet specific operational needs. They use advanced sealing techniques to ensure a tight and reliable seal, crucial for preventing leaks. Additionally, many models include visual indicators to confirm the closure is securely locked, enhancing safety further.

Together, these features make Vertical Quick Opening Closures indispensable for industries requiring frequent access to pressurized systems, combining robust performance with safety and operational efficiency.

Benefits and Operation

One of the primary benefits of Vertical Quick Opening Closures is their ability to significantly reduce the time required to access a vessel or pipeline. Operators can open and close these closures rapidly, which is particularly valuable during emergency situations or when multiple access points need regular maintenance. Additionally, their vertical orientation makes them suitable for installations with limited horizontal space but sufficient vertical clearance.

Operationally, these closures are engineered for ease of use. They typically include features like hand wheels or hydraulic actuators that facilitate smooth opening and closing actions. Safety features such as pressure release valves and interlocks ensure that the closures can only be operated under safe conditions, preventing accidents.

Applications

In practical applications, operators often use Vertical Quick Opening Closures in filtration systems, separators, and reactors. These systems require regular cleaning or swapping of internal components. Operators also employ these closures in sampling systems. Any application needing periodic internal inspections for compliance and performance benefits from these closures.

Overall, Vertical Quick Opening Closure is invaluable for their safety, efficiency, and adaptability. They are the preferred choice in industries needing quick, safe access.

Vertical Quick Opening Closures (QOCs) are crucial in various industrial applications beyond just the typical use in filtration systems, separators, and reactors. They are particularly valuable in the oil and gas industry, where they facilitate rapid access for the inspection and maintenance of pipelines and storage tanks, helping to prevent costly downtime due to prolonged shutdowns. In chemical manufacturing, these closures allow for safer handling of volatile or hazardous substances by minimizing exposure during system access.

Additionally, Vertical QOCs are also vital in water treatment facilities and pharmaceutical manufacturing. In these settings, they enable quick system openings for regular sanitation and quality control inspections, ensuring compliance with stringent health and safety standards. The adaptability of these closures also makes them suitable for power generation plants. Here, they help maintain critical systems like steam turbines and boilers, allowing for quick inspections and repairs.

The design of Vertical QOCs, which ensures they can be operated quickly and safely, supports operational continuity in these diverse environments. Their robust construction protects against environmental conditions and operational stress, preserving system integrity over time. This combination of features makes Vertical QOCs indispensable in sectors where system reliability and safety are paramount.

There are no reviews yet.