Introduction to Corrosion Coupon Monitoring

Corrosion Coupon Monitoring is an indispensable practice in industrial maintenance. It is crucial to assess the rate of corrosion within infrastructure such as pipelines, storage tanks, and processing equipment. By strategically placing pre-weighed metal coupons within a system, operators can effectively observe the extent of corrosive damage over time. These coupons, crafted from the same material as the system components, undergo periodic inspection and analysis after being exposed to the operational environment.

Consequently, the weight loss recorded from these coupons is instrumental in calculating the corrosion rate, providing valuable insights into the material’s durability and the effectiveness of any corrosion control measures. This data becomes essential for planning maintenance, forecasting equipment lifespan, and ensuring system safety and reliability, thereby safeguarding the integrity of critical infrastructure.

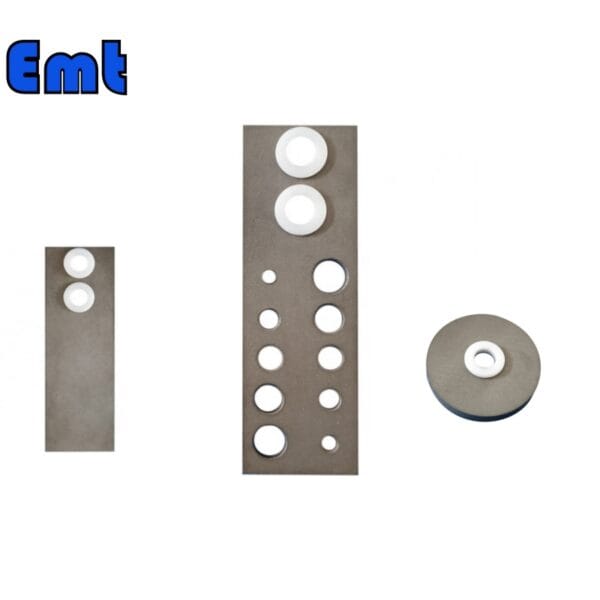

Corrosion coupon types

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) | 3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes | Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

Selection Model of the Corrosion Coupon

| Model | ||||||

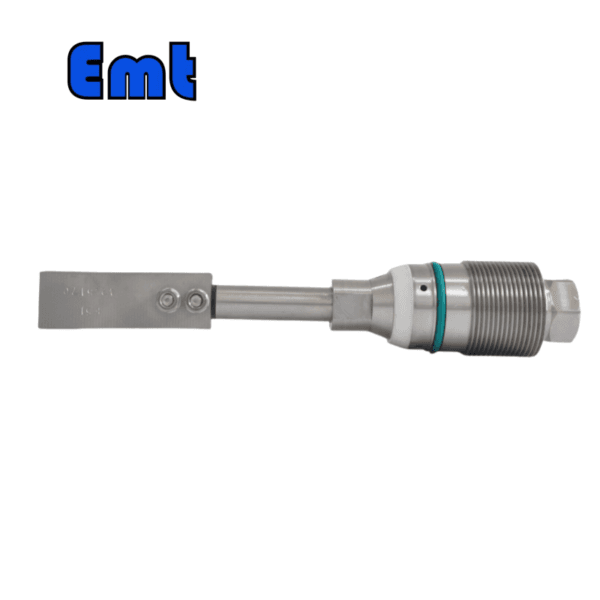

| EMT-CIPA | Access Fitting Body of Corrosion Coupon | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if the flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example, EMT-CIPA-0F600#RF-2-1/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, 1/2″NPT(F)Tee, Protective Cover in CS without hole | ||||||

Corrosion coupon using the method

Select the Material: Choose corrosion coupons that match the material composition of your system to ensure accurate results.

Install Coupons: Place the coupons in a coupon rack or directly in the flow stream of the system.

Expose Coupons: Allow the coupons to remain in the system for a predetermined period, typically between 30 to 90 days.

Retrieve Coupons: After the exposure period, remove the coupons from the system for analysis.

Clean Coupons: Clean the coupons using appropriate solvents or cleaning agents to remove any corrosion products or deposits.

Weigh Coupons: Weigh the cleaned coupons to determine the amount of material lost due to corrosion.

Calculate Corrosion Rate: Use the weight loss data to calculate the corrosion rate, typically expressed in mils per year (mpy).

Analyze Data: Analyze the corrosion rate data to assess the system’s corrosion levels and determine the efficacy of any corrosion inhibitors.

Report Findings: Document and report the findings to relevant stakeholders for further decision-making on maintenance and protection strategies.

Repeat Monitoring: Regularly repeat the process to continuously monitor the corrosion and maintain the integrity of the system.

When should people use corrosion coupon monitoring?

Corrosion coupon monitoring is essential in various situations to maintain infrastructure integrity and longevity. Initially, you should implement it to establish a baseline corrosion rate when commissioning a new system or after significant modifications. Include it in routine maintenance to monitor ongoing corrosion and evaluate the effectiveness of corrosion control measures.

After any operational changes like adjustments in fluid composition, temperature, or pressure, reassess corrosion rates. Also, utilize these coupons when introducing or altering corrosion inhibitors to assess their effectiveness over time. Compliance with industry regulations often requires regular corrosion monitoring to prevent system failures and leaks.

Incorporating corrosion coupon monitoring as a preventive strategy can help detect early signs of corrosion. Addressing these signs promptly can prevent extensive damage and system failures, ultimately extending the lifespan of the infrastructure.

Corrosion Coupon Monitoring matters that need attention

Corrosion Coupon Monitoring requires careful attention to detail to ensure accurate and useful results. First, proper placement of the coupons is crucial. Place them in representative areas of the system where they mimic the actual conditions faced by the system’s materials. This ensures the data accurately reflects the true corrosion environment.

Additionally, it’s important to ensure that the coupons are securely installed. They should not come into direct contact with any other metal parts to avoid galvanic corrosion effects. Regularly schedule the retrieval and analysis of the coupons. Consistency in monitoring intervals provides a reliable dataset for assessing corrosion trends.

After retrieval, thorough cleaning of the coupons is necessary to remove all corrosion products before weighing. This step is critical for obtaining accurate measurements of material loss. Finally, interpret the data carefully, considering all operational variables that might influence the corrosion rate. This comprehensive approach allows for effective maintenance planning and system optimization, enhancing the overall safety and longevity of the infrastructure.

There are no reviews yet.