The Chemical Injector Quill is a vital component designed for precise chemical injection into pipelines, playing a crucial role in maintaining pipeline integrity and efficiency. This injector is specifically engineered for use in industries such as building material shops, construction works, energy and mining, pipeline pigging, and oil & gas pipelines.

1. Product Overview:

- Product Name: China Manufacturer Chemical Injector Quill

- Brand Name: EMT Pigging

- Condition: New

2. Technical Specifications:

- Material Construction: Available in Stainless Steel 304, 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625 for exceptional corrosion resistance and durability.

- Working Temperature Range: -20℃ to +200℃, capable of handling varying operational environments.

- Working Pressure Ratings: Available in 150LB, 300LB, 600LB, 900LB, and 1500LB, to suit different pipeline pressures.

- Injector and Sealing Materials:

- Injection Tube and Solid Plug Assembly: 316L Stainless Steel

- NPT Nozzle: 316L Stainless Steel

- Sealing Material: Fluororubber for optimal chemical resistance and sealing performance.

- ISO 9001 Certified – Ensuring quality and reliability in manufacturing and operational processes.

3. Features:

High Durability and Low Maintenance

The EMT Chemical Injector Quill is engineered with resilience in mind, utilizing robust materials such as Stainless Steel 304, 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625. These materials are chosen for their exceptional resistance to corrosion and ability to withstand extreme conditions, including high temperatures and aggressive chemical exposures. This construction ensures the injector quill remains operational over extended periods with minimal maintenance. The design is optimized to reduce wear and tear, thereby lowering the frequency and costs associated with repairs and replacements.

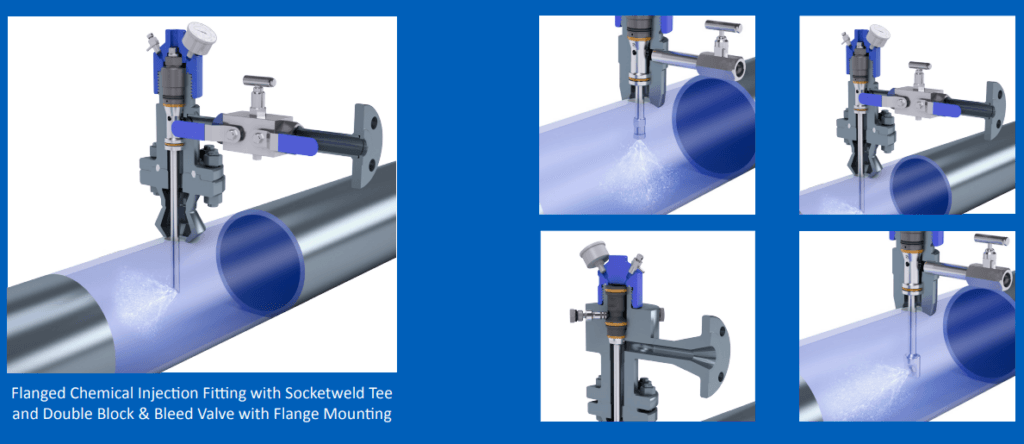

Flexible Installation

Adaptability in installation is a key feature of the EMT Chemical Injector Quill. It supports various mounting options, including 2″ flange, 2″ Flareweld access fitting, and 1″ Nipple to NPT ball valve connections. This range of options provides compatibility with a wide variety of pipeline systems and configurations, making it easy to integrate into existing infrastructures without the need for extensive modifications. The flexible installation capabilities allow for seamless integration in diverse operational setups, ensuring that the system can be tailored to meet specific site requirements and constraints.

Safety and Efficiency

Safety is paramount in the design of the EMT Chemical Injector Quill. It allows for the injection of chemicals under operating pressure. Which is a critical feature for maintaining continuous pipeline operations without shutdowns. This capability not only enhances safety by reducing the risk of exposure during chemical injection processes but also improves operational efficiency by minimizing downtime. The injector’s design includes safety features such as fluororubber seals which provide reliable containment of chemicals, preventing leaks and exposure. Additionally, the precise control over chemical dosage and injection rates ensures effective treatment and protection of the pipeline, further enhancing the overall efficiency and safety of pipeline operations.

4. Applicable Industries:

- Particularly useful in settings requiring regular maintenance and monitoring, such as building material shops, construction works, energy and mining operations, pipeline pigging, and oil & gas pipeline systems.

5. Advantages:

Easy Operation

The EMT Chemical Injector Quill`s engineered for simplicity and precision, making it straightforward for operators to use. Its intuitive design minimizes the complexity typically associated with chemical injection systems. Features like clearly marked controls and easy-access fittings ensure that chemical delivery can be managed with high accuracy, reducing the likelihood of errors during injection. This user-friendly approach helps maintain consistent chemical dosing, which is critical for effective pipeline treatment and protection.

High Efficiency and Cost-Effectiveness

Efficiency and cost-effectiveness are paramount in the design of the EMT Chemical Injector Quill. It is built to last, thanks to its use of durable materials that withstand the rigors of industrial environments, thereby extending the lifespan of the device and reducing the need for frequent replacements. The injector’s efficient operation minimizes the waste of chemicals, ensuring that every injection is optimized for maximum effect while minimizing costs. Moreover, its high operational efficiency reduces downtime and maintenance expenses, making it a highly economical option for long-term pipeline maintenance.

Lightweight and Flexible

The EMT Chemical Injector Quill is lightweight and flexible, facilitating easy handling and installation. Its compact size and reduced weight make it manageable for a single technician to install, which is particularly beneficial in remote or difficult-to-access locations. The flexibility of the mounting options allows it to be adapted to various pipeline configurations effortlessly, reducing the time and labor typically required for setup. This flexibility not only speeds up the installation process but also makes it easier to relocate or adjust the injector as needed to accommodate system changes or upgrades.

6. Packaging and Delivery:

- Selling Units: Single item

- Package Size: 40 x 40 x 80 cm

- Gross Weight: 10 kg

- Our Service1.Many kinds of chemical injection with different type to meet difference requirements.

2. The fastest feedback!

3. Also the fastest delivery time.

4.At last, 24 hours,7 days online.

There are no reviews yet.