Introduction To Pig Launcher and Receiver

Our EMT Pig Launcher and Receiver technical requirements comply with the provisions of the Technical Specification for the Pig Launcher and Receiver of the Pig for Oil and Gas Pipeline Engineering (CDP-S-PC-MA-011-2009/B)

Our EMT quick opening closure has many features. You can open and close it flexibly. They are light and have reliable sealing without leakage, and a safe automatic interlock device. The opening time of the QOC should be less than 2 min. The opening torque is less than 200Nm. For other technical requirements, our EMT QOC meets the CDP-S-PC-MA-015-2009/B.

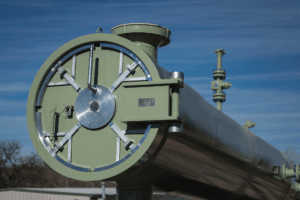

A pig launcher typically consists of a steel pipe that matches the diameter of the pipeline to be cleaned or is about 100mm larger to accommodate different sphere sizes. Manufacturers mount a flange cover at the device’s front end for pig loading and an air inlet, the size of which depends on the air volume. The back end of the pig launcher connects to the pipeline and may feature either a welded or flanged connection, often including a reducer, depending on the sphere’s size.

The pig receiver has an air release valve in the front (above) for pressure relief and air defense in the pipeline. It also has a sewage outlet in the lower part to remove debris and accumulation.

Types of Pipeline Pigs

There are many types of pipeline pigs. They are roughly divided into three types:

- pigging ball (round rubber ball)

- cup cleaning pig (caliper pig, isolation pig, bidirectional pig)

- foam pig (high, middle, low density)

The advantage of the cup pig is that it can maintain a fixed orientation when running in the pipe. It can also carry a variety of testing instruments and other devices. Such as detecting the deformation of the pipeline, replacing the medium cleaning the space in the pipe, and removing the rust on the pipe wall.

Why should you launch the pig?

How to make sure to receive the pig successfully?

Operating Steps of Launching the Pig

Preparation

(1) Empty the waste oil tank. Check the status of each valve. You should open the bottom valve of the safety valve.

(2) Open the quick-opening closure, clean the sealing ring, and grease it.

(3) Put in the pig and push the pig to the size of the head; Close the closures. Make sure the closures are closed.

(4) Open the ball valve of the balance pipe at the front end of the service cylinder. Then open the by-pass valve of the ball valve of the service cylinder inlet (first open the small ball valve of the low pressure end, and then open the small ball valve of the high pressure end) to feed the oil. After that open the exhaust valve on the cylinder to vent the gas. Then observe the level of the contaminated oil tank. Close the exhaust valve if the rise is significant. Wait 1-2 minutes to vent again and close the exhaust valve. Close the by-pass valve of the ball valve at the service cylinder inlet.

(5) Confirm the execution of pig sending procedures.

Launching Process

(1) Open and open the ball valve of the pig launcher. Open the service cylinder outlet ball valve after the outlet ball valve is fully opened.

(2) After the outlet ball valve is fully opened, the outbound ball valve is closed (the inlet ball valve of the service cylinder is interlinked with the outlet ball valve and the outbound ball valve), and the process is switched to the pig sending process. Pig indicator signal alarm, pig out of station.

(3) Wait a few minutes, then confirm that the pig has left the station and open the outlet ball valve. Once the outlet ball valve is fully open, close both the service cylinder inlet ball valve and the outlet ball valve. The service cylinder inlet ball valve is linked with the outlet ball valve. This action restores the flow to its normal direction. Finish sending pig job.

(4) Empty the oil in the cylinder and carry out nitrogen purging. Empty the tank.

Operation Precautions

(1) All relevant personnel are in place, take the walkie-talkie, and keep in touch with the station control room. Prepare necessary tools such as adjustable wrenches.

(2) During the service, pay attention to the status of each valve and the switching sequence, and operate strictly according to the procedure to prevent the occurrence of pressure bouncing.

(3) Pay attention to personal safety, do not stand on the opposite side of the quick opening closure.

(4) If it is found that the pig is not sent out or the outbound pressure rises significantly, it may be that the pig is stuck in the pipeline. Should be reported to the dispatch room in time, according to the situation to decide whether to stop.

There are no reviews yet.