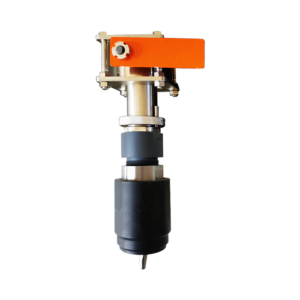

The EMT Welded Pipeline Pig Signaller, an explosion-proof device, is non-electrical and aims to monitor pipelines efficiently. It provides adjustable probing depth and signals pig passage reliably. Its versatility lies in easy installation, inspection, and maintenance across different pipeline thicknesses.

The Weld Pig Signaller monitors pig passage in pipelines, offering easy installation and compatibility with various indicators. It simplifies pig detection with an English operating system, aiding pipeline cleaning with its reliability and cost-effectiveness. Electrical contacts can enable remote signal transmission for sound, light, and electricity displays. The base welds onto the pipe, containing a striker for pig detection, triggering visual confirmation upon pig transit. Manual resetting prevents misjudgments, while stainless steel parts ensure durability and prevent leakage with rubber seals for sealing. Adjustments to the indicator base allow versatility across different pipe diameters and pig sizes.

Installation and Inspection

To install and inspect the Pipeline Pig Signaller, determine and adjust the pin extension length based on the pipeline thickness. Ensure the pin axis is positioned correctly above the inner wall of the pipeline. Record the relative position for reference. Next, insert the pig signaller with the adjusted extension length into the pipeline opening, aligning it parallel to the pipeline direction. Securely weld the base to the pipeline following welding requirements. After cooling, apply lubricating oil to the sealing surfaces before reassembling the movement onto the base. Confirm alignment and tighten the locking nut to prevent movement rotation, ensuring efficient monitoring of pig passage in the pipeline.

Working Principle of Pipeline Pig Signaller

The movement’s end on the base features a bi-directional trigger pin that extends into the pipeline near the wall. As the pipeline pig passes, the pin triggers, pulling the link rod and causing the flag indicator cap to pop up, staying raised until manually reset, signaling pig passage. Following the pig’s passage, the pin resets automatically. If a manual reset is needed, pressing down the flag indicator cap puts it in standby mode; failure to reset indicates the pig’s presence at that point.

Indicator Types

| Indicator Types | ||||

|  |  |  | |

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Maintenance

The non-metallic sealing ring seals the pipeline medium between the base and the movement of the welded base flag indicator. To disassemble the movement for repair or replacement, use a flat-blade screwdriver to remove the sealing ring, labeling it for storage carefully. When installing a new movement, always use a new seal ring.

Reuse a used sealing ring only with the same movement. If a leak occurs, first check the lock nut. If it is tightened, consider reinstallation if the sealing surface was not clean during installation. Clean the Pipeline Engineering Pig Signaller if contaminated by viscous materials by removing and disassembling the stainless steel cylinder and its components.

Parameters of Pipeline Pig Signaller

| Name | Pig Signaller |

| Connection | 2” Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

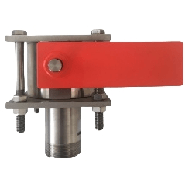

Components

A welded pipeline pig signaller typically includes the following components:

Housing: Encloses and protects the internal mechanisms.

Sensor: Detects the passage of the pig through the pipeline.

Indicator: Provides a visual or electronic signal when a pig passes.

Mounting Base: Welds onto the pipeline, securing the signaller in place.

Seal: Ensures the system is watertight and prevents leaks.

Advantages

The EMT Pig Signaller, featuring a 2” welded base and NPT connection, offers various advantages. It boasts removability through a special retriever, simplifying maintenance and enabling swift replacement or repositioning. Equipped with a uni-directional trigger powered by a magnet, it ensures consistent and precise pig detection unaffected by pipe pressure fluctuations. The signaller allows for a 20mm insert depth adjustment, facilitating precise positioning post-welding for optimal pig detection efficiency. With a welded connection, it provides installation flexibility by allowing welding at any point along the pipe, streamlining the installation process while ensuring proper material matching for effective welding.

Welded Connection Process

When installing a pig signaller with a welded connection, adhere to the following welding process for optimal results. Firstly, focus on welding the base exclusively, ensuring the absence of other components during this phase. To maintain base stability, firmly press the base to prevent any movement or deflection. Initiate welding by symmetrically securing the base with four points, then proceed with continuous and symmetrical welding to avoid base deformation. Post-welding, allow the signaller to cool down before inspecting for deformations, especially focusing on preserving the integrity of the sealing surface. Following inspection, prepare the sealing surface by applying sealing grease to guarantee effective sealing and readiness for installation.

There are some operation cautions as follows:

During the operation of a pig signaller, exercise caution to avoid over-tightening components, maintain proper alignment, conduct regular inspections for wear, adhere to manufacturer guidelines, prevent contact with contaminants, and ensure correct resetting after pig passage to uphold the device’s functionality and accuracy in monitoring pig movement within the pipeline.

There are no reviews yet.